Seam In Sheet Metal

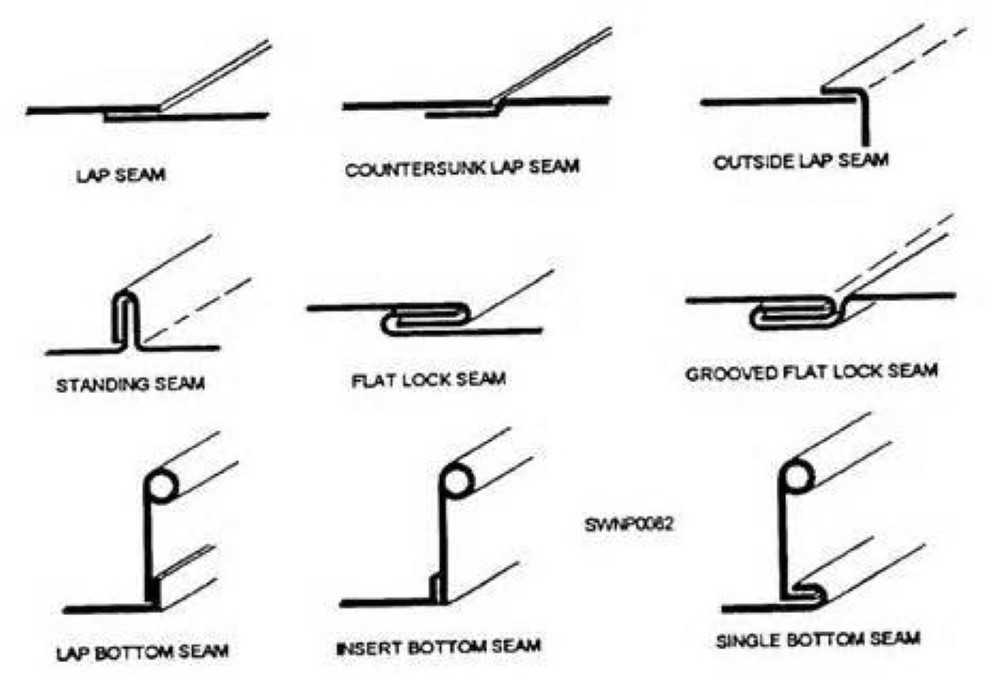

Seam In Sheet Metal - Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. There are three types of lap seams: Each section of duct can. Hemming is the process in which. The plain lap seam, the offset lap seam, and the corner lap seam (fig. The seam is highlighted in the below image. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.

Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. There are three types of lap seams: Each section of duct can. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. Hemming is the process in which. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The seam is highlighted in the below image. The plain lap seam, the offset lap seam, and the corner lap seam (fig.

Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. The seam is highlighted in the below image. The plain lap seam, the offset lap seam, and the corner lap seam (fig. There are three types of lap seams: Each section of duct can. Hemming is the process in which. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.

INCH Technical English pictorial seams & hems (sheet metal)

The seam is highlighted in the below image. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. Each section of duct can. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. There are three types.

Metal Seams Inspection Gallery InterNACHI®

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. The plain lap seam, the offset lap seam, and the corner.

Sheet Metal Seams MEP Academy

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The seam is highlighted in the below image. There are three types of lap seams: Hemming is the process in which. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects.

Standing Seam Roofing System Western Counties Roofing

Each section of duct can. There are three types of lap seams: Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. Hemming is the process in which. The plain lap seam, the offset lap seam, and the corner lap seam (fig.

Standing seam metal roof sanychristian

Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. The plain lap seam, the offset lap seam, and the corner lap seam (fig. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Each section of duct can..

Standing Seam Aluminum Metal Roofing Sheets Buy standing seam metal

Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. There are three types of lap seams: Hemming is the process in which. Each section of duct can. The seam is highlighted in the below image.

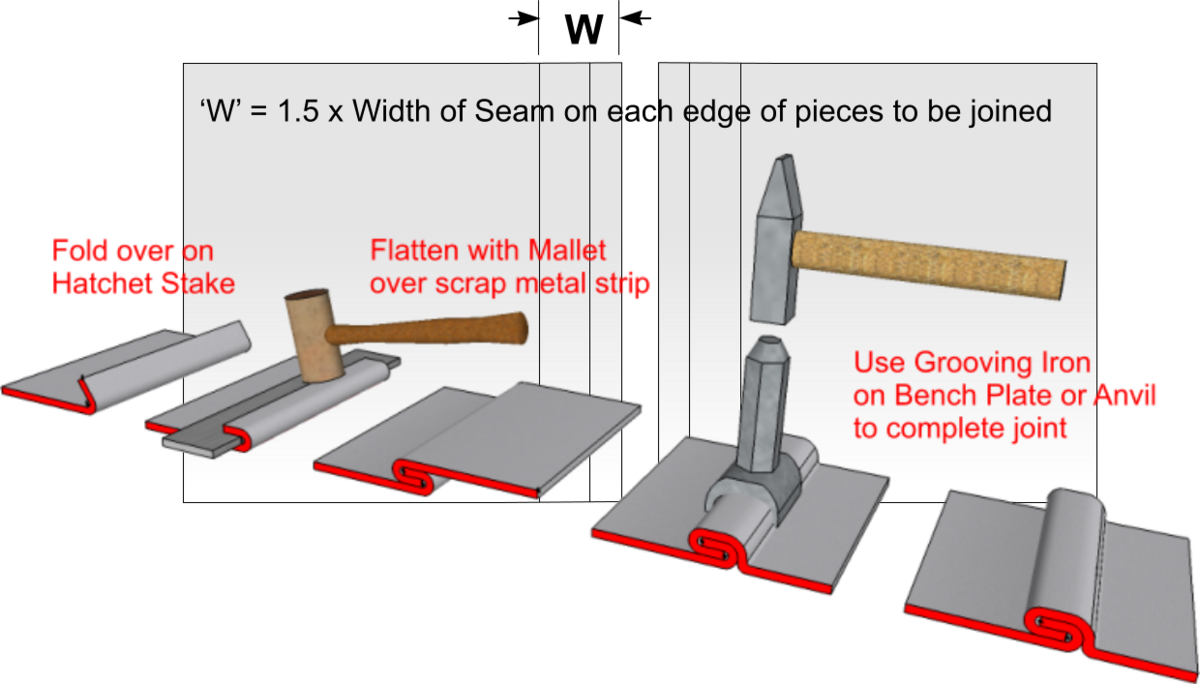

Grooved Seam Joint DT Online

The seam is highlighted in the below image. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. There are three.

Sheet metal standing seam 3D Warehouse

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. The seam is highlighted in the below image. There are three.

Model T Ford Forum Any "tin benders" sheet metal workers out there

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which. Each section of duct can. There are three types of lap seams: Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture.

Galvalume vs galvanized standing seam metal roof Metal Roof Experts

Hemming is the process in which. There are three types of lap seams: Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Each section of duct.

The Seam Is Highlighted In The Below Image.

Hemming is the process in which. Web the seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together. The plain lap seam, the offset lap seam, and the corner lap seam (fig. Each section of duct can.

Hemming And Seaming Are Two Similar Metalworking Processes In Which A Sheet Metal Edge Is Rolled Over Onto Itself.

Web a variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. There are three types of lap seams: